Key Highlights

- Predictive maintenance cuts unplanned downtime by 30-50% using sensor data

- Manufacturing analytics delivers 18-25% maintenance cost reductions industry-wide

- Real-time quality control prevents defects before they reach production lines

- Demand forecasting accuracy improves by 20-30% with predictive models

- ROI typically achieved within 12-18 months of predictive analytics deployment

Introduction

Cut downtime by half—predictive analytics transforms manufacturing from reactive chaos to proactive precision.

Picture a production line where machines predict their own failures weeks in advance, quality issues are corrected before defects occur, and supply chains adapt to demand shifts in real-time.

This isn’t science fiction—it’s the reality I help manufacturers achieve every day through predictive analytics.

After spending over a decade transforming manufacturing operations through data analytics, I’ve learned one critical truth: unplanned downtime costs industrial manufacturers an estimated $50 billion each year. This isn’t just a statistic—it’s millions of production hours lost to preventable equipment failures, quality issues, and supply chain disruptions.

The manufacturers winning today aren’t the ones with the newest equipment or largest budgets. They’re the ones leveraging predictive analytics in manufacturing to anticipate problems before they happen.

I’ve watched plants cut downtime by 50%, reduce maintenance costs by 25%, and improve quality metrics by double digits—all within 12-18 months of implementing the right analytics strategy.

Why Manufacturing Needs Predictive Analytics Now

The Fourth Industrial Revolution has fundamentally redefined manufacturing excellence. Industry 4.0 isn’t just about robotics and automation—it’s about creating intelligent, self-optimizing production ecosystems powered by data analytics in manufacturing industry applications.

The global manufacturing predictive analytics market reached USD 1,604.0 million in 2024 and is projected to grow at a CAGR of 16.2% to reach USD 6,617.4 million by 2033, reflecting the explosive demand for predictive analytics in manufacturing industry solutions.

Traditional manufacturing operates on a reactive model: equipment breaks, production stops, teams scramble to repair, and margins erode. Deloitte’s Industry 4.0 research shows that poor maintenance strategies can reduce a plant’s overall productive capacity between 5 and 20 percent. The average manufacturer faces approximately 800 hours of unplanned machine maintenance and downtime annually, equivalent to about 15 hours per week of paid non-productive time.

The critical pain points driving adoption include:

- Unplanned downtime devastation: A single hour of stopped production can cost manufacturers $50,000 to $260,000 depending on industry and scale. In automotive manufacturing specifically, downtime now exceeds $2 million per hour due to just-in-time production dependencies.

- Quality unpredictability: Traditional inspection catches defects after production, wasting materials and customer trust. Manufacturing analytics transforms this by detecting parameter drift before defects occur, enabling proactive quality control rather than reactive scrap management.

- Supply chain volatility: Demand swings, supplier disruptions, and inventory imbalances plague manufacturers lacking real-time forecasting. The pandemic exposed these vulnerabilities, but manufacturing data analytics offers resilience through probabilistic planning and advanced demand sensing.

- Workforce challenges: As experienced technicians retire, tribal knowledge evaporates. Predictive systems codify expertise into algorithms, enabling newer workers to make veteran-level decisions about maintenance timing and production adjustments.

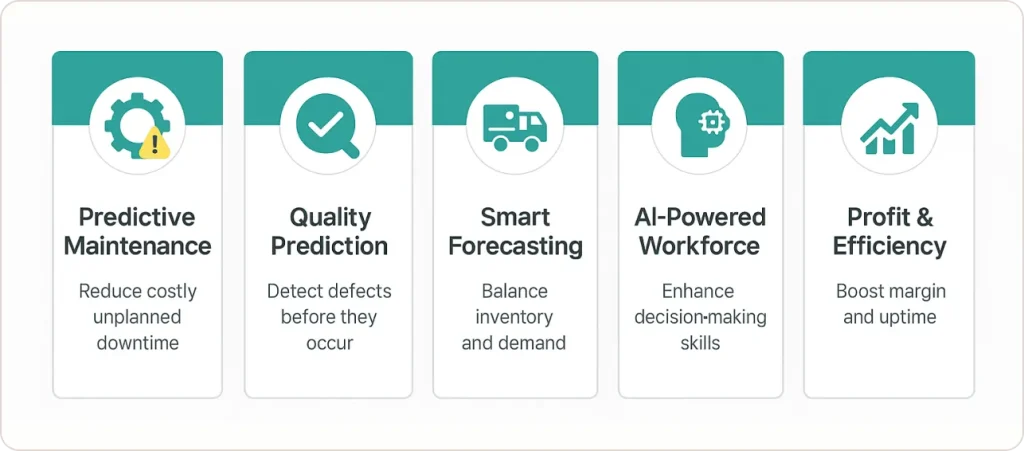

Top Benefits of Predictive Analytics in Manufacturing

The business case for predictive analytics in manufacturing rests on tangible, measurable outcomes. Here’s what manufacturers consistently achieve:

Predictive Maintenance: Slash Downtime & Costs

I’ll never forget touring a mid-sized automotive parts manufacturer whose maintenance strategy centered on “run it till it breaks.”

After implementing predictive maintenance through vibration sensors and thermal imaging integrated with machine learning models, their downtime plummeted from 15% to 6% within 18 months.

Deloitte research demonstrates that manufacturers implementing predictive maintenance systems report a 30-50% reduction in machine downtime and a 10-40% decrease in maintenance costs.

How it works: IoT sensors continuously monitor equipment health—tracking vibration patterns, temperature anomalies, acoustic signatures, and performance degradation. Machine learning algorithms analyze these patterns and predict failures days or weeks before they occur.

The financial impact:

- 30-50% reduction in unplanned downtime

- 10-40% decrease in maintenance costs

- 12-18 month payback periods on implementation investment

- Ongoing annual savings that compound for years

In short: Predictive maintenance uses sensor data to catch problems before they stop production—saving hundreds of thousands in emergency repairs and lost output.

Optimized Production & Quality Control

Gartner research indicates that business intelligence and data analytics software ranks as the top software purchase for U.S. manufacturers, with 79% of businesses expecting positive ROI within 18 months.

Aberdeen Group research shows that manufacturers using predictive quality analytics experience a 35% decrease in quality-related defects and an 18% reduction in quality costs compared to industry averages.

Manufacturing analytics transforms quality control from reactive inspection to proactive prevention.

I’ve consulted with consumer electronics manufacturers who previously relied on end-of-line testing. By implementing real-time quality analytics monitoring process parameters—temperature, pressure, cycle times, material properties—they detect drift before defects manifest.

Real-world success: Bosch’s implementation of predictive quality analytics in their automotive component production reduced customer complaints by 90%. Their system monitors thousands of process parameters in real-time, flagging anomalies that human operators would miss.

Production optimization delivers:

- 35% decrease in quality-related defects

- 10-15% improvement in overall equipment effectiveness (OEE)

- Earlier detection of process drift preventing scrap and rework

- Energy efficiency through optimized operating conditions

Bottom line: Real-time analytics catches quality problems before they become scrap—saving materials, labor, and customer relationships.

Supply Chain Resilience Through Forecasting

Implementation of predictive demand forecasting has enabled manufacturers to reduce inventory levels by an average of 25% while maintaining or improving service levels.

I’ve worked with clients managing thousands of SKUs, hundreds of suppliers, and volatile demand patterns.

Traditional ERP forecasting often fails because it relies on linear assumptions in non-linear environments. Machine learning models incorporate dozens of variables—seasonality, economic indicators, weather patterns, social media sentiment, competitor actions—to predict demand with 20-30% greater accuracy than traditional methods.

Supply chain impact: Ford Motor Company applied predictive analytics to inventory management and reduced carrying costs by 30% while maintaining service levels.

Their system dynamically adjusts reorder points and safety stock based on predicted demand variability, supplier reliability, and lead time uncertainty.

What manufacturers gain:

- 20-30% improvement in forecast accuracy

- 25-30% reduction in inventory carrying costs

- Better service levels with less working capital tied up in stock

- Improved supplier relationship management through predictive risk assessment

Implementing comprehensive Manufacturing Data Analytics Solutions across supply chain operations enables manufacturers to achieve end-to-end visibility, from supplier performance monitoring to demand signal analysis, creating a resilient and responsive supply chain ecosystem.

Key takeaway: Better forecasting means less cash tied up in inventory while still meeting customer demand on time.

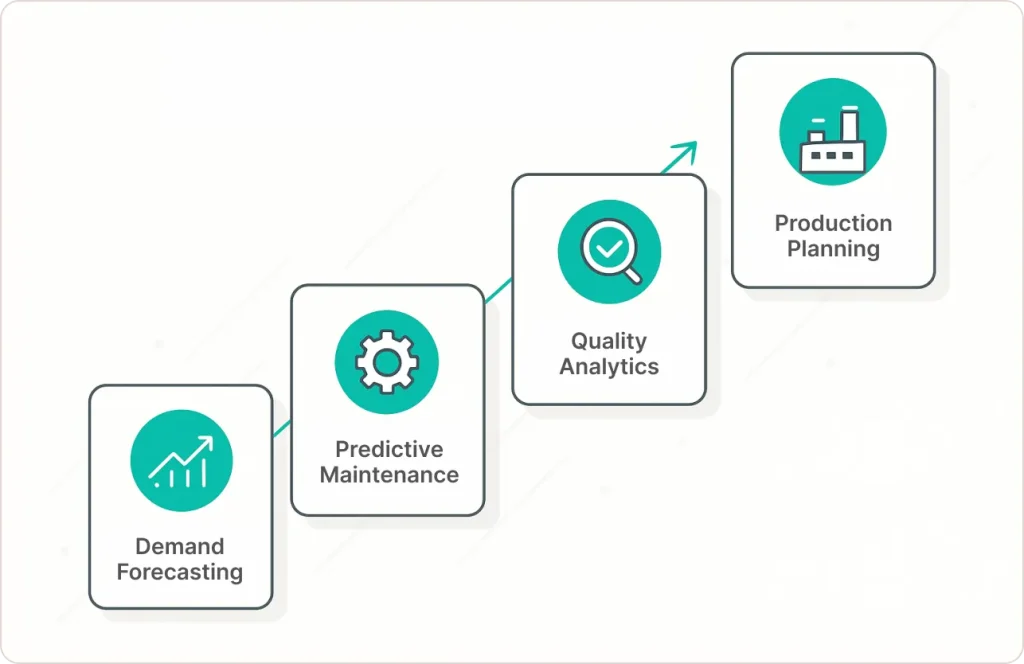

Key Use Cases Driving ROI

Manufacturing predictive analytics delivers measurable value across multiple operational areas. Here’s where leading manufacturers see the fastest returns:

Demand Forecasting & Inventory Optimization

Traditional forecasting methods struggle with modern market complexity. Advanced predictive analytics in manufacturing incorporates external data sources—economic indicators, weather forecasts, social media trends—into demand models.

One consumer goods manufacturer I advised integrated real-time retail point-of-sale data with production planning through comprehensive manufacturing data analytics, reducing forecast error by 40% and improving customer fill rates from 87% to 96%.

Key benefits:

- 20-30% improvement in forecast accuracy

- 25% reduction in inventory carrying costs

- Better service levels with less working capital tied up

Predictive Maintenance & Asset Management

Beyond preventing failures, predictive maintenance optimizes the timing of preventive interventions. In 2024, 35% of manufacturing firms utilized AI technologies, especially in areas like predictive maintenance and quality control, with 90% of top machine manufacturers investing in manufacturing predictive analytics technology for maintenance operations.

I’ve helped plants eliminate unnecessary preventive maintenance—servicing equipment on condition rather than calendar schedules—saving 15-20% on maintenance labor and parts while improving availability.

Real-world impact:

- 30-50% reduction in unplanned downtime

- 15-20% savings on maintenance costs

- Extended equipment lifespan through optimized service timing

Real-Time Quality Analytics

Computer vision combined with predictive analytics revolutionizes quality control. Aerospace manufacturers now use AI-powered inspection systems that detect microscopic defects invisible to human inspectors, ensuring zero-defect delivery for critical components.

Results manufacturers achieve:

- 35% decrease in quality-related defects

- 90% reduction in customer complaints (Bosch case study)

- Earlier defect detection saving materials and rework costs

Production Planning & Scheduling

Optimizing production schedules becomes exponentially complex with product variety, changeover times, and resource constraints. I’ve implemented predictive scheduling systems that simulate thousands of scenarios to identify optimal sequences minimizing setup time and maximizing throughput while respecting delivery commitments.

Operational gains:

- 25% reduction in changeover time

- 10-15% improvement in overall equipment effectiveness (OEE)

- Better on-time delivery performance

How Predictive Analytics Works: Technology Foundation

Data Collection Through IoT Sensors

Predictive analytics begins with comprehensive data collection. Modern industrial IoT sensors are inexpensive, reliable, and easily integrated:

- Vibration sensors on rotating equipment (motors, pumps, gearboxes)

- Temperature sensors monitoring bearing temperatures and process conditions

- Acoustic sensors detecting unusual sounds indicating wear

- Pressure transducers in hydraulic and pneumatic systems

- Current sensors monitoring electrical consumption patterns

- Performance metrics from existing SCADA/MES systems

Most predictive models require 3-6 months of data capturing normal operations to train algorithms recognizing degradation patterns.

Machine Learning Models

I typically employ several modeling approaches:

- Supervised learning: When historical failure data exists, algorithms learn patterns preceding failures. Random forests, gradient boosting machines, and neural networks excel at capturing complex, non-linear relationships.

- Anomaly detection: Unsupervised learning establishes normal operating envelopes, flagging deviations indicating potential issues even for failure modes never previously observed.

- Time series forecasting: Demand prediction and capacity planning leverage ARIMA or LSTM neural networks capturing seasonality, trends, and complex temporal patterns.

Real-Time Integration

Predictive insights only create value when actionable. I design systems that integrate analytics directly into operator workflows:

- Real-time dashboards displaying equipment health scores

- Mobile alerts for maintenance technicians

- Automated work order generation

- Integration with CMMS/EAM systems

Visualization matters enormously. I’ve seen analytically sophisticated systems fail because outputs were incomprehensible to floor personnel.

Effective dashboards use intuitive health scores, traffic light indicators, and plain-language recommendations—not complex statistical outputs.

The payoff: Technicians get clear “fix this machine next week” alerts instead of drowning in raw sensor data.

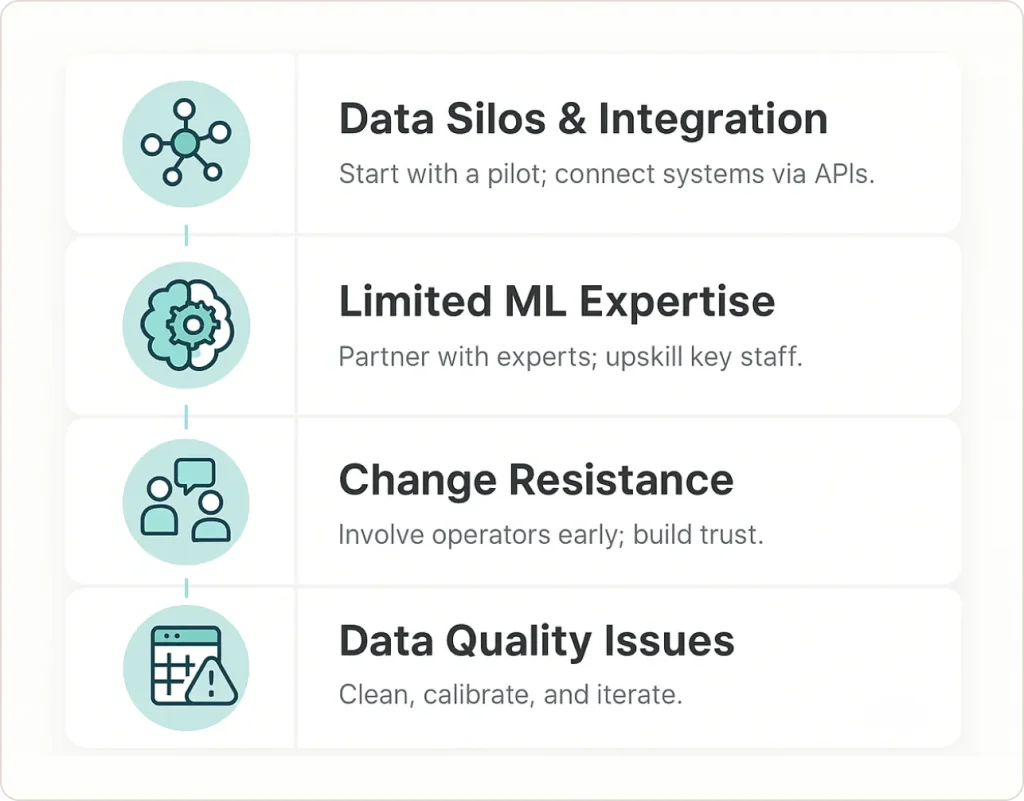

Overcoming Implementation Challenges

Implementing predictive analytics isn’t without obstacles. Here’s how I help clients navigate common challenges:

Data silos and integration complexity:

- Start with a pilot focusing on a single production line or asset class. Demonstrate value before tackling enterprise-wide integration.

- Use middleware and APIs to connect legacy systems without requiring wholesale replacement.

Limited ML expertise:

- Most manufacturers lack in-house data scientists. Partner with experienced analytics consultancies that understand both manufacturing operations and advanced analytics.

- Train operations personnel in basic analytics concepts so they can interpret model outputs.

Change management resistance:

- I’ve encountered skeptical operators who distrust “black box” algorithms. Involve floor personnel from day one.

- Demonstrate model performance alongside existing intuition. Start with advisory systems that assist rather than override human judgment.

Poor data quality:

- Implement data governance practices. Clean historical data. Establish sensor calibration protocols.

- Accept that initial models may be imperfect—iterate and improve as data quality increases.

- Organizational culture must shift from firefighting to prevention, from experience-based to evidence-based decision-making. This human element often determines success more than technical sophistication.

Future Trends Reshaping Manufacturing Analytics

The global predictive analytics market is projected to grow from $22.22 billion in 2025 to $91.92 billion by 2032, exhibiting a CAGR of 22.5%, driven by increasing IoT adoption and improving AI capabilities in data analytics in manufacturing industry applications.

- Digital twins: Virtual replicas of physical assets enable simulation-based optimization. Manufacturers can test production scenarios, maintenance strategies, and process changes virtually before implementing physically, creating a new frontier for manufacturing predictive analytics.

- AI-driven manufacturing execution systems: Next-generation MES platforms incorporate embedded AI that automatically optimizes production sequences, quality parameters, and resource allocation without human intervention, leveraging advanced manufacturing analytics capabilities.

- Edge AI and 5G connectivity: Ultra-low latency 5G networks combined with edge AI chips enable millisecond-response predictive systems for applications like robotic quality inspection and real-time process control in manufacturing data analytics workflows.

- Sustainability analytics: As ESG reporting becomes mandatory, predictive analytics in manufacturing will increasingly focus on environmental impact—predicting emissions, optimizing energy usage, and enabling circular economy initiatives through comprehensive data analytics in manufacturing industry frameworks.

Conclusion: Transform Your Operations Through Data Intelligence

The $50 billion annual downtime challenge facing manufacturers isn’t inevitable—it’s addressable through predictive analytics. I’ve witnessed the transformation firsthand: plants moving from crisis management to proactive optimization, from reactive firefighting to anticipatory precision, from guesswork to evidence-based decision-making.

The competitive advantage increasingly belongs to manufacturers who harness their operational data through advanced analytics. McKinsey’s Industry 4.0 research indicates that manufacturers implementing advanced analytics solutions have achieved productivity gains of 10-15% and reduced downtime by as much as 50%.

The implementation journey requires technical expertise, organizational commitment, and realistic expectations. Start with high-impact pilots. Demonstrate value quickly. Expand incrementally. Partner with experienced advisors who understand both manufacturing operations and advanced analytics.

The future of manufacturing belongs to data-driven organizations. The question isn’t whether to implement predictive analytics—it’s how quickly you can deploy it to maintain competitive advantage in an increasingly intelligent industrial landscape.